Are Baseballs Really Made of Leather?

Contents

Why are baseballs made of leather? And what kind of leather is it? We investigate the answer to these questions and more in our latest blog post.

The History of Baseballs

Baseballs have been made of various materials throughout history including leather, rubber, and cork. The composition of baseballs has changed as well, with the introduction of synthetic materials. The stitching on baseballs has also evolved, from hand-sewn to machine-made. Let’s take a closer look at the history of baseballs.

The first baseballs

The first baseballs were made by hand, and were much softer than today’s balls. In the 1800s, players would often stitch their own balls to save money. The stitching left marks on the ball that hitters could use to help them hit the ball more effectively.

Eventually, factories began mass-producing baseballs, and the quality of the balls improved. In 1872, the first standardized rules for baseball were created, and it was stipulated that the balls used in games must be “made of yarn and leather and covered with leather.”

Today, most baseballs are still made of cowhide leather. The hides are gathered from slaughterhouses and tanned in massive drums. Once they are tanned, the hides are cut into strips and sent to a factory where they are formed into balls.

The transition to leather baseballs

In the early days of baseball, the balls were often made of makeshift materials like yarn wound around a piece of rubber. As the game became more popular and organized, the balls were made of higher-quality materials like leather. The stitching on these early baseballs was often crude, and the balls themselves were often irregular in shape.

In 1858, A.G. Spalding, who would go on to become one of the biggest names in baseball, was a pitcher for the local Chicago team. He noticed that the balls used in games were often inferior, and he set out to make a better ball. After experimenting with a number of materials, he settled on cowhide as the best option.

Spalding’s balls were an instant hit, and soon other companies were making similar balls. The transition to leather baseballs was complete, and it changed the game forever. The ball was now more durable, which meant that it could be hit harder and farther. This in turn led to bigger stadiums and more fans.

Today, all major league baseballs are still made of cowhide leather. They are tightly wound with yarn and have 108 stitches per ball. The Major League Baseball logo is stamped on each ball, and each one is hand-inspected before being used in a game.

The Making of a Baseball

It all starts with the cow. Tanned cowhide is shipped to the baseball factory where it is cut into small panels. Then, those panels are sewn together by hand to form the cover of the baseball. From there, the baseball is filled with a cork center, wrapped in yarn, and then covered with another layer of cowhide. Finally, the baseball is stamped with the league logo and is ready to be used in a game.

The materials

Most baseballs are made of cowhide leather, and the rest are made of horsehide. The stitching is usually made of red thread because it is stronger than other types of thread and it stands out against the white background of the ball. The core of the ball is typically made of cork, rubber, or a mixture of both.

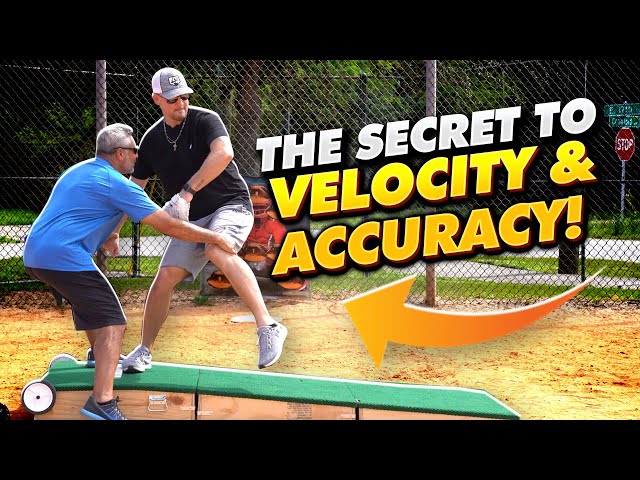

The stitching

Did you know that it takes 108 stitches to sew together a baseball? If those stitches are not even, the ball will be lopsided and will not fly through the air properly. A machine called a “long arm” is used to sew the baseball. The long arm has a needle that is 3 feet long!

The Quality of a Baseball

The testing process

The process of creating a baseball is actually quite simple. Raw hide is tanned and turned into a thick sheet, which is then cut into circles. Those circles are sewn together with 108 stitches, and the ball is then covered with a special mixture of red rubber and cork. It’s not until after all of that that the ball is covered in cowhide leather.

But not all baseballs are created equal. In order to be used in an official Major League game, a baseball must meet specific guidelines set by the MLB. For example, the baseball must have a circumference between 9 and 9 1/4 inches, and it must weigh between 5 and 5 1/4 ounces. It must also be made of cowhide leather, with a cork center and 108 stitches.

To ensure that each batch of baseballs meets these standards, they are put through a rigorous testing process. First, the raw hide is inspected to make sure it meets the MLB’s standards for thickness and hardness. Then, each ball is weighed and measured to ensure it falls within the acceptable range for circumference and weight. Once the balls have passed these initial tests, they are sent off to be sewn together.

After the balls are sewn, they are checked again to make sure the stitching meets MLB guidelines. Once they pass that inspection, they are carefully hand-stuffed with cork cores before being covered in rubber. The rubber is then inspected to make sure it meets MLB standards for hardness and density. Finally, each ball is given a final inspection before being wrapped in cowhide leather and shipped off to stadiums around the country.

The impact of weather

One factor that can have an impact on the quality of a baseball is the weather. If it’s been a particularly rainy season, the baseballs can get wet and cause them to swell. This can make them harder to throw and could potentially cause injuries. In addition, if the baseballs are stored in a humid environment, they can mildew and become structurally unsound.

The Future of Baseballs

With the recent uptick in home runs, Major League Baseball is considering changing the composition of the baseball. In the past, baseballs were made of leather and stuffed with cork. The cork was removed in the late 1800s, and the baseballs have been made of cowhide leather ever since.

New materials

There has been a lot of discussion in recent years about the materials that baseballs are made of. While the traditional leather baseball has been used for many years, some newer materials are being considered as well.

One of the most popular new materials being considered is rubber. Rubber baseballs have several advantages over leather ones. They are cheaper to produce, so they would save money for both leagues and manufacturers. They also last longer, so players would not have to replace them as often.

Another material that is being considered is synthetic leather. This material is already used in other sports, such as football and basketball. It has many of the same advantages as rubber, but it also closely resembles traditional leather baseballs. This could make the transition to synthetic leather easier for both players and fans.

only time will tell which material will become the new standard for baseballs. But one thing is for sure: the game will continue to evolve, and the materials used to make its balls will be one area that sees some change in the future.

Improved stitching

A baseball is a ball used by players of the sport of baseball to throw and catch. A baseball is made up of a leather cover, cork center, and winding. It is hit with a bat to score runs. The stitching on a baseball must be strong enough to withstand the forces exerted on it when the ball is hit with a bat.

In recent years, there have been reports of balls breaking during use. In some cases, this has resulted in players being injured. As a result, there has been increased scrutiny on the manufacturing of baseballs.

One area that has been targeted for improvement is the stitching. In 2016, the Major League Baseball (MLB) approved the use of new, stronger stitches on baseballs. These stitches are less likely to break than traditional stitches. As a result, players are less likely to be injured by broken balls.

The new stitches are not the only change that has been made to baseballs in recent years. The MLB has also approved the use of synthetic materials in baseball covers. These materials are more durable than leather and are less likely to tear during use.

The use of synthetic materials and stronger stitches has led to increased safety for players. It is hoped that these changes will reduce the number of injuries caused by broken baseballs.