Who Makes MLB Baseballs?

Contents

MLB baseballs are hand-stitched by Rawlings in Costa Rica. The process of making a baseball is fascinating and each ball is unique.

Rawlings

Rawlings does in fact make the official MLB baseball. They have been making baseballs for the MLB since 1887. Rawlings also manufactures baseballs for the Minor Leagues, the NCAA, and other professional baseball organizations.

Company History

Rawlings Sporting Goods Company, Inc. is an American sporting goods company based in St. Louis, Missouri. The company specializes in baseball, basketball, and gridiron football equipment, making it the official supplier for Major League Baseball and the National Football League. It is also a supplier for the National Hockey League and Minor League Baseball.

The company was founded in 1887 by George Rawlings in St. Louis. The name “Rawlings” was already being used by another company when George Rawlings bought the name for $75. He started the company by selling his handmade baseball gloves. In 1905, Rawlings released the Montana Gold Glove whichRevolutionized baseball and became very popular among MLB players.

TheRawlings factory moved from downtown Saint Louis to an old farmhouse just outside town in 1945. The move took place because of World War II’s restrictions on transportation and gasoline usage; it was easier to transport workers to the factory than vice versa given these restrictions Then, in 1957, Rawlings moved again to a larger facility where they’re currently headquartered today on Locust Street.

How Rawlings Baseballs are Made

Major League Baseballs are hand-stitched in Costa Rica from top-quality cowhide. The cowhide is shipped to the Rawlings factory in Turrialba, where it is hung to cure for 60 days. After curing, the hide is cut into panels and sales representatives hand select the panels that will be used to make baseball covers.

After the panels are chosen, they are sent to a stamping machine that imprints the Rawlings logo, the baseball stitching design and other important information onto thepanel. The stamped panel is then cut into two pieces; one piece will eventually become the front cover of the ball and the other will be used for the back cover.

Once the panels are cut, they are sent to a machine that laces them together with red thread. After the front and back cover are lace together, they are ready to be stuffed. A worker at the Rawlings factory puts 108 double stitches around a cork-rubber core and three layers of wool windings aroundthe cork. Once the ball is stuffed, a colored stitch is used to close upthe opening where the wool was added.

After the baseball is stitched, it is coated with rubber cement and left to dry for 24 hours. Once it has dried, a worker hand-seals any tiny openings in the ball with more rubber cement. The next step is to add a layer of black stuffing material aroundthe ball, which gives it its distinct black color. The final step inmaking a Rawlings baseball is to add another layer of rubber cementbefore hand-stitching a red leather patch overthe opening wherethe black stuffing was added.

Wilson

With over a hundred years of experience, Wilson is a trusted name in the baseball industry. They are the official ball provider for Major League Baseball, and have been since the early 1900s. Wilson has a long history of innovation in the baseball world, and their balls are used by some of the biggest names in the game.

Company History

Wilson has been making baseballs since 1858, and they have been the official ball of Major League Baseball since 1977. In addition to baseballs, Wilson also manufactures other sports equipment, including basketballs, footballs, golf balls, and tennis balls.

The company was founded by Harvey Hatch Wilson in Massachusetts. Wilson started out by selling hand-sewn cricket balls and later began manufacturing baseballs for use in the newly-formed National League. In 1905, Wilson’s grandson A.G. Spalding took over the company and oversaw its growth into a major sports equipment manufacturer. Today, Wilson is a subsidiary of the Finland-based Amer Sports Corporation.

How Wilson Baseballs are Made

Wilson has been making baseballs since 1884, and they are currently the official ball of Major League Baseball. Every year, Wilson produces roughly 3.2 million hand-sewn baseballs that are used in every MLB game. So, how are they made?

It all starts with cowhide that is tanned and cut into thin strips. Those strips are then cut into small pieces that will eventually become the baseball’s cover. Once the cover pieces are cut, they’re sent to a embroidery factory where they’re stitched together with a cotton thread.

After the covers are stitched together, they’re sent back to Wilson where they’re placed over a rubber core. The rubber core is made of three layers: a winding layer of yarn, a cushioning layer of black rubber, and a center layer of red rubber. Once the cover is placed over the rubber core, it’s hand-stitched shut.

After the baseball is assembled, it’s placed in a machine that bonds the cover to the rubber core. Once that’s done, each ball is individually inspected and then packaged up and shipped off to be used in Major League games.

Other MLB Baseball Brands

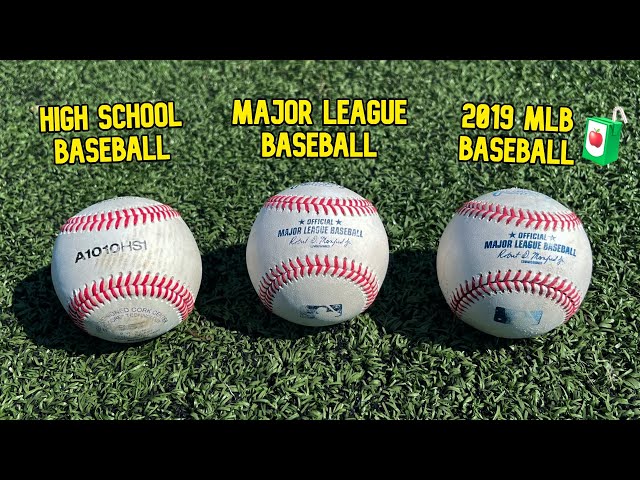

MLB baseballs are made by Rawlings, but there are other brands of baseballs that are used in the major leagues. Some of the other brands are Wilson, Diamond, and Mizuno. Let’s take a look at some of the differences between these brands.

Diamond

Diamond is the official baseball of Major League Baseball. The company has been in business since 1889 and has been manufacturing baseballs for the MLB since 1977. Diamond baseballs are made in America and are hand-stiched with American-made wool yarn.

Worth

Worth is one of the major manufacturers of MLB baseballs. Worth has been making baseballs for over 100 years and is one of the most trusted brands in the industry. Worth baseballs are used in all levels of play, from little league to the major leagues.

Rawlings Gold Glove

Rawlings Gold Glove balls are made specifically for games played in the major leagues. They are hand-selected from each lot of baseballs produced by Rawlings to ensure they meet the company’s high standards for quality and consistency.

Rawlings Gold Glove balls are wound tighter than other balls to provide greater strength and durability. They also have a higher-quality leather cover and a more uniform seam height to ensure a better grip for pitchers and a more predictable flight path for batters.

The Rawlings Gold Glove ball is also used in the World Series, All-Star Game, and other Major League Baseball postseason play.