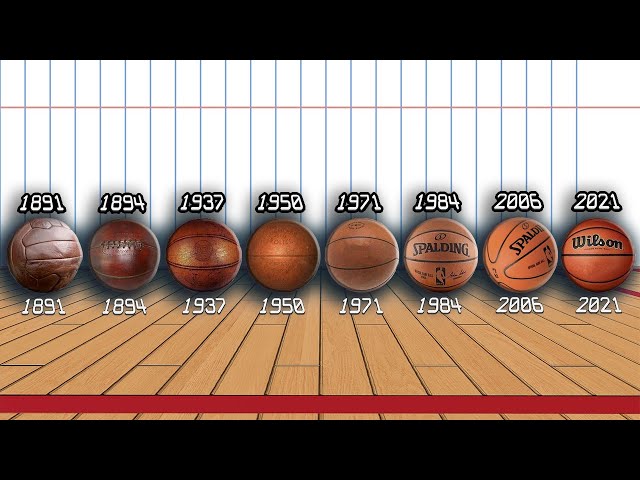

Who Makes The Nba Basketballs?

Spalding is the official manufacturer of NBA basketballs. They have been making NBA basketballs since 1983.

The NBA and Wilson

The National Basketball Association (NBA) is a men’s professional basketball league in North America; composed of 30 teams (29 in the United States and 1 in Canada). It is widely considered to be the premier men’s professional basketball league in the world. NBA players are the world’s best paid athletes by average annual salary per player.

The NBA and Wilson have a partnership

The NBA has a partnership with Wilson and is the exclusive provider of basketballs for the league. That means every game, from the regular season to the finals, is played with a Wilson basketball.

Wilson has been the official ball supplier for the NBA since 2006

The National Basketball Association (NBA) is the premier professional men’s basketball league in North and features the best players from around the world. The NBA has been using Wilson basketballs since 1946, when the company became the first-ever official ball supplier for the league. In 2006, Wilson once again became the official ball supplier for the NBA, having been outfitted with that distinction for nearly 60 years.

How are Wilson basketballs made?

Wilson is the official basketball of the NBA, and has been for over 30 years. Wilson basketballs are made in Ada, Ohio in the United States of America. The company has been making basketballs since the early 1900s, and they are now a subsidiary of the Finnish company Amer Sports.

The process begins with the cover

Wilson is the exclusive manufacturer of NBA game balls. The process begins with the cover, which is made of premium full-grain leather that has been tanned in a process that uses naturally sourced materials and takes over three weeks. The cover is then hand-stitched around a bladder that is made of butyl rubber, which provides excellent bounce and air retention.

After the cover and bladder are put together, the ball is ready for final inspection before it can be used in an NBA game.

The cover is made of leather or synthetic leather

Leather or synthetic leather are the two most common materials used to make the cover of a basketball. The material affects the feel and grip of the ball, and also how long it will last.

Wilson basketballs have a synthetic leather cover. This makes them more durable than balls with a leather cover, which is why Wilson basketballs are the official ball of the NBA.

The cover is then stitched to the ball

After the cover is cut to the desired shape and size, it is then stitched to the ball. The number of panels and their shapes vary depending on the manufacturer, but a typical basketball has between 8 and 12 panels. Once the cover is stitched on, a valve is added so that air can be pumped into the ball.

The bladder

The bladder, typically made of latex, is the part of the ball that holds the air. It is typically made of latex. The bladder is what makes the ball bouncy. It is also the part of the ball that is stitched to the outer cover.

The bladder is made of rubber or latex

The bladder is the innermost layer of the ball, and it’s made of rubber or latex. It’s what gives the ball its shape and bounce. The material and construction of the bladder determine how long the ball will retain its shape and how bouncy it will be.

The bladder is inflated with air

To start, the bladder is inflated with air. Next, the carcass is wrapped around the bladder. The carcass is made of four pieces of leather that are stitched together. Once the carcass is wrapped around the bladder, it is inflated to 9-10 psi. Next, two sternum plates are placed on either side of the ball and the ball is again inflates to 9-10 psi. Finally, the ball is covered with a pebbled composite leather and given its official circumference, weight, and size.

The final steps

The last few steps in the process are the most important. The ball is now ready to be shipped all over the world so that people can play the game that they love.

The ball is then tested

After the ball is sewn together, it goes through a series of tests. The first is a bounce test. A machine drops the ball from a set height onto a concrete floor. The ball must bounce between 51 and 54 inches when measured from the center of the ball to the floor. If it doesn’t, it’s sent back for more work.

The second test is called the inflation test. A machine pumps air into the ball until it reaches its correct inflation level of 7.5 to 8.5 pounds per square inch. Once it passes that test, the ball is ready for use in an NBA game!

The ball is then packaged and shipped

After the ball is weighed and approved, it is then packaged and shipped to the NBA. There are currently three official game ball suppliers for the NBA: Spalding, Rawlings and Wilson. The vast majority of balls used in the NBA are produced by Spalding, which has been the league’s official game ball supplier since 1983.