Why Are Tennis Balls Vacuum Sealed?

Contents

If you’ve ever wondered why tennis balls are vacuum sealed, you’re not alone. It’s a common question, and the answer is actually pretty interesting. Keep reading to learn more about why tennis balls are vacuum sealed and how it affects their performance.

The History of Tennis Balls

Tennis balls were first used in the game of tennis in 1874. The first tennis balls were made of cloth and filled with cork. The cork made the ball heavier so it would bounce more. The problem with the cork was that it would compress over time and the ball would not bounce as well. In 1880, the first rubber ball was used in tennis. The rubber ball was lighter and bouncier than the cork ball.

Early tennis ball development

Tennis is a game that has been around for centuries, with the first recorded game taking place in 11th century France. The game has undergone many changes over the years, but one constant has been the ball. Early tennis balls were made of leather and filled with hollow sheep’s wool. They were incredibly bouncy, but also very heavy, making them difficult to play with. In the 16th century, the balls began to be made of cloth-covered rubber. These balls were lighter and easier to play with, but they did not bounce as well as the leather balls. It was not until 1875 that vulcanized rubber was used to make a ball that combined both lightness and bounce. This ball, known as a “Celluloid” ball, quickly became the standard for tennis balls.

The first real innovation for tennis balls came in 1935 when Slazenger released a ball made of vulcanized rubber with a felt covering. This ball was much lighter than the standard Celluloid ball and did not absorb as much water, making it superior for playing on grass courts. The felt covering also made the ball spin more, making it easier to control. The Slazenger Wimbledon ball quickly became the standard for all tennis tournaments.

The next major innovation came in 1976 when Penn released a ball made of synthetic rubber and nylon. This ball was designed to have less bounce than the standard Slazenger Wimbledon ball so that it would slow down play on clay courts. This “slow”ball soon became the standard for all clay court tournaments. In 1986, Wilson released a “low-compression”ball that was designed to have less bounce than the Penn “slow”ball so that it would slow down play on hard courts. This low-compressionball soon became the standard for all hard court tournaments.

Today, tennis balls are made of highly elastic rubber with a woven fabric covering. They are filled with pressurized air or nitrogen and are regulated by size and weight standards set by the International Tennis Federation (ITF). All tennis balls used in official tournament play must be covered with yellow or white felt and have a diameter between 2.54 cm (1 inch) and 6.86 cm (2-11/16 inches). They must also weigh between 56 grams (1.98 ounces) and 58 grams (2 ounces).

The introduction of the rubber ball

The first tennis balls were made of cloth stuffed with feathers. They were very light and didn’t bounce well. In 1875, the Liverpool Rubber Company started selling rubber balls. They were much heavier than the feather balls, but they bounce better. In 1877, the U.S. National Lawn Tennis Association (now the United States Tennis Association) decided to standardize the size and weight of tennis balls. They chose a ball that weighed 3 ounces and had a diameter of 2.86 inches.

Tennis balls were originally white, but in 1986, the International Tennis Federation (ITF) changed the color to optic yellow so that they would be easier to see on television. The ITF also decided that all tennis balls must be marked with the ITF logo and that they must have a uniform feel so that players could have consistency from one ball to another.

Today, most tennis balls are made of rubber with a felt covering. The felt is important because it helps slow down the speed of the ball as it hits the ground, making it easier for players to control their shots. The core of the ball is made from synthetic rubber because it doesn’t compress as much as natural rubber does. This makes the ball bounce more consistently. The covering is stitched on by hand and then glued to the core.

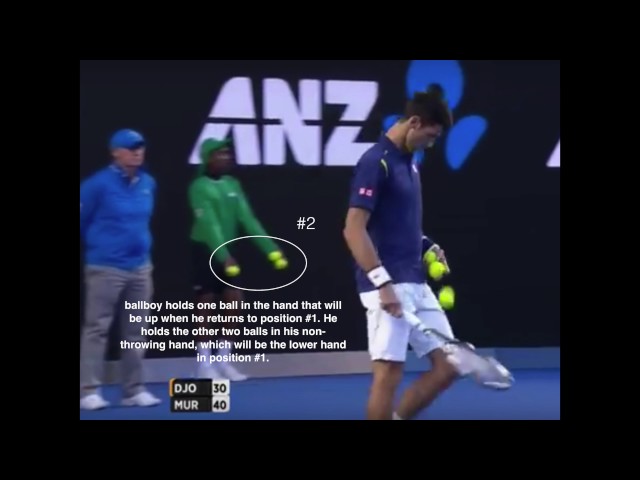

Once the balls are made, they are put into pressurized cans where they are vacuum-sealed so that they will stay fresh until they are used

The Benefits of Vacuum Sealing

Vacuum sealing has become a popular way to store food and keep it fresh for a longer period of time. However, did you know that vacuum sealing can also be used for other things? In this article, we will discuss the benefits of vacuum sealing and why tennis balls are vacuum sealed.

Improved bounce

Vacuum sealing a tennis ball can improve its bounce by up to 25%. The airtight seal prevents the escape of air, which would otherwise cause the ball to lose some of its bounce.

In addition to improving the performance of the ball, vacuum sealing also extends its life. By preventing air and moisture from entering the ball, vacuum sealing prevents the growth of mold and mildew, which can cause the ball to deteriorate.

Better shelf life

One of the primary benefits of vacuum sealing is that it extends the shelf life of food. ByRemove air from the packaging, you also remove oxygen, which is one of the primary causes of spoilage. In fact, vacuum sealed foods will last three to five times longer than their non-sealed counterparts.

Not only does this mean that you can buy in bulk and save money, but it also means that you can cook in bulk and have ready-to-eat meals on hand for those busy nights when cooking is not an option. Simply pop a pre-sealed meal in the microwave or oven and dinner is done!

Vacuum sealing also keeps food fresher tasting because it slows down the growth of mold and bacteria. When foods are exposed to air, they begin to lose their flavor and texture as oxidation occurs. This process is accelerated by heat, light, and moisture, all of which are present to some degree in most home kitchens. Vacuum sealing eliminates these factors and allows food to retain its flavor and texture for much longer periods of time.

Enhanced performance

Vacuum sealing keeps tennis balls at their optimum performance by preventing them from drying out, which affects their bounce. By storing them in a pressurized, nitrogen-filled environment, the balls retain their original hardness, making them last longer and perform better.

Vacuum sealed tennis balls are also less likely to go flat over time. This is due to the fact that they are not exposed to the air, which causes them to slowly lose air pressure and become softer.

Tennis balls that are vacuum sealed will also maintain their color and design for a longer period of time. This is because the sun’s ultraviolet rays can cause the print on the ball to fade.

The Drawbacks of Vacuum Sealing

tennis balls can go flat over time, and as a result, they have to be replaced frequently. If you are a tennis player, you know how frustrating this can be. However, there is a way to prolong the life of your tennis balls- by vacuum sealing them.

Lessened air circulation

One of the main drawbacks to using vacuum sealed bags for long-term storage is the lack of air circulation that can cause spoilage. When food is stored in a vacuum sealed bag, it is in an airless environment. This can cause bacteria and mold to grow, as well as hasten the spoiling process. Additionally, because vacuum sealed bags are so tightly closed, they can cause foods to become soggy or stale over time.

Deformation over time

One of the major drawbacks to sealing in a vacuum is that, over time, things will start to lose their shape. This is due to a process known as “outgassing.” Any time a material is exposed to a vacuum, it will release some of its molecules into the surrounding area. If the object being sealed is made of a porous material like cloth or paper, this can cause it to lose its shape and become deformed.

The Future of Tennis Balls

Tennis balls are highly pressurized with nitrogen gas. They are then sealed in a canister or jar before being shipped off to the stores. The canister keeps the tennis balls fresh for a longer period of time. When you are ready to use them, you can cut open the canister and the tennis balls will be as good as new!

New materials

One of the biggest changes to tennis balls in recent years has been the switch from natural rubber to synthetic rubber. Natural rubber is made from the sap of rubber trees, while synthetic rubber is made from petroleum. Synthetic rubber is cheaper and more durable, but some players prefer the feel of natural rubber.

In addition to changing the material of the balls, manufacturers are also experimenting with new textures and surface treatments. These new tennis balls might have dimples or raised patterns that change the way they bounce and spin. Some companies are even making eco-friendly tennis balls that degrade quickly after being used.

It’s likely that tennis balls will continue to evolve in the years to come as manufacturers try to create the perfect ball for every player.

Better manufacturing processes

To meet increasing consumer demand, tennis ball manufacturers have had to better their manufacturing processes. In the past, it was not uncommon for tennis balls to be made with second-hand materials. However, this is no longer the case. Today, all tennis balls are made with new materials that are carefully monitored for quality assurance. In addition to using new materials, manufacturers have also improved their production processes. For example, many companies now use robotic machines to wind the thread around the core of the ball. This ensures that each ball is wound evenly and with consistent tension. All of these improvements have resulted in a higher quality product that can be enjoyed by all.