What Are Baseballs Really Made Of?

Contents

- The history of baseballs

- The composition of baseballs

- How baseballs are made

- The difference between Major League and minor league baseballs

- The difference between regulation and commemorative baseballs

- The physics of baseballs

- The science of baseballs

- The psychology of baseballs

- The economics of baseballs

- The future of baseballs

We all know that baseballs are made of leather and stitches, but have you ever wondered what they’re really made of? In this blog post, we’ll take a look at the materials that make up a baseball, and how they come together to create the perfect game day ball.

The history of baseballs

Few people know that baseballs are made of a variety of materials, including rubber, cork, string, and leather. The exact composition of a baseball has been the subject of much debate over the years, as different manufacturers have used different materials in their balls.

The first baseballs were made of yarn and stuffed with feathers. These balls were extremely light and often flew out of the ballpark. In 1858, H. Chandler Harrowgate introduced the first rubber-Red Baseball These balls were much heavier than their feather-stuffed predecessors and did not fly as far.

Cork-cored baseballs were introduced in 1876 and quickly became the standard. These balls were lighter than rubber-cored balls and flew further when hit. In 1900, the American League adopted a slightly larger ball that was easier to see, but this ball did not last long as it proved difficult to grip and throw.

In 1910, the modern baseball was introduced. This ball was made of yarn wound around a cork center and covered with leather. The ball was smaller than its predecessors and had a smoother surface that made it easier to grip and throw. This design has remained largely unchanged for over 100 years and is still used today in Major League Baseball games.

The composition of baseballs

Baseballs are made of a variety of materials, but the core is typically made of cork, rubber, and yarn. The cover is usually made of leather. The stitching that holds the cover in place is also usually made of yarn.

The composition of baseballs has changed over time. In the early days of baseball, balls were often made of cowhide or horsehide. These days, synthetics are often used in place of natural materials. The cork at the center of the ball is often replaced with rubber or some other synthetic material. The yarn that is used to stitch the ball together can also be synthetic.

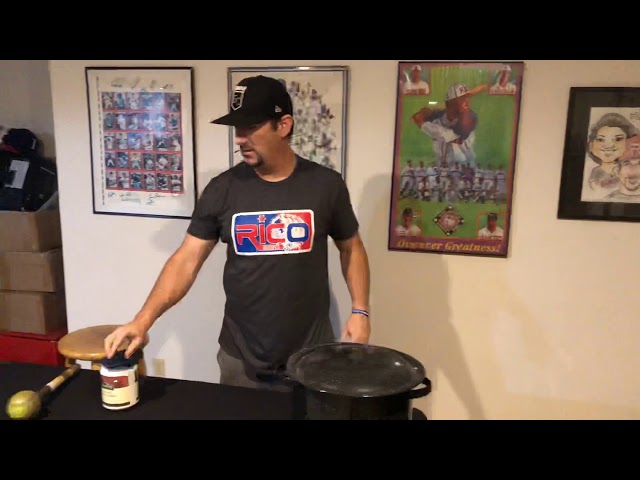

How baseballs are made

Baseballs are made of three main materials: cowhide, cork, and rubber. The cowhide is used for the cover, the cork is used for the center, and the rubber is used for the core.

Baseballs have been made of these three materials since 1858, when they were first introduced. The cover is made of two pieces of leather that are stitched together. The cork is then placed in the center of the ball, and the rubber is placed on top of that. The whole ball is then covered with another layer of leather.

The stitching on a baseball is very important. It has to be just right in order for the ball to be playable. If the stitching is not done correctly, the ball can come apart and be dangerous to both the players and the fans.

Today, baseballs are still made of these three traditional materials. However, they are now also made with synthetic materials that help improve their performance. For example, some baseballs now have a synthetic cover that helps them keep their shape better than a traditional leather cover.

The difference between Major League and minor league baseballs

Major league baseballs are made of cork covered by black rubber, then wound with yarn and covered with a cowhide leather jacket. Minor League baseballs are made of synthetic materials, which means they don’t have the same lifespan as Major League baseballs.

The difference between regulation and commemorative baseballs

Baseballs have been around for well over a century, and the game has changed a lot in that time. One thing that has stayed relatively constant, however, is the ball itself. Though there have been some rule changes and slight modifications over the years, the basic design of the baseball has remained largely the same. That being said, there are still some notable differences between regulation baseballs and commemorative baseballs.

Regulation baseballs are made of cowhide leather, with a cork center and a rubber or synthetic rubber core. The balls are then covered with a thin layer of black mud, which helps them keep their shape and gives them some extra grip. They are also stamped with the official major League Baseball logo to show that they meet all the necessary requirements.

Commemorative baseballs, on the other hand, can be made of any material, as long as they meet certain size and weight requirements. They also don’t have to be stamped with the MLB logo, though many still are. These balls are often given as souvenirs at special events or sold as collectibles.

So, while there are some differences between regulation and commemorative baseballs, they are both still technically considered “baseballs” under the rules of the game.

The physics of baseballs

The history of the baseball can be traced back to the early 1800s, when it was first used as a Game Ball in cricket. Since then, the baseball has evolved into the sport we know and love today. But what exactly are baseballs made of?

The answer may surprise you: baseballs are actually made of multiple layers of different materials, all designed to come together to create the perfect flight pattern and striking surface. The components of a baseball include:

The outer layer: This is typically made from cowhide or horsehide, and is responsible for the distinctive red stitching that runs around the circumference of the ball.

The core: The heart of the baseball is typically made from either cork or rubber. This material is compressed to create a hard, yet lightweight, center that will not deform when hit by a bat.

The inner layer: This final layer is made from multiple pieces of silk thread that are tightly wound around the core. This layer gives the ball its smooth surface and makes sure that it maintains its shape after being hit.

The science of baseballs

Whether you’re a die-hard baseball fan or just enjoy watching the occasional game, you’ve probably wondered what exactly a baseball is made of. It turns out that there’s quite a bit of science that goes into the manufacturing of these small, round objects.

Baseballs are made of three main parts: the core, the winding, and the cover. The core is made up of four layers of cork mixed with rubber. This mixture is then covered with a layer of black rubber, which is where the winding comes in. The winding is made up of yarn that is wound tightly around the ball. Finally, the cover is made of cowhide leather that has been hand-stitched by a professional.

One of the most important aspects of a baseball is its stitching. The stitches must be even and strong in order to hold the ball together and keep it from falling apart. If a baseball is not properly stitched, it can come unraveled and cause serious injuries to players.

Now that you know what baseballs are made of, you can appreciate them even more the next time you see a game!

The psychology of baseballs

What are baseballs really made of? There is a lot of psychology that goes into the construction of a baseball. The seams, the size, the weight, and even the color can all affect how a pitcher throws a ball and how a hitter tries to hit it.

It has been suggested that the seemingly random composition of baseballs may in fact be carefully designed to produce the desired results. For example, it has been theorized that the red stitches on a baseball may help pitchers better see the ball as they throw it. Additionally, the weight and size of a baseball can affect how fast it travels when thrown, and how far it can be hit when batted.

While the exact composition of a baseball may be a closely guarded secret, there is no doubt that there is a lot of thought that goes into its construction. Whether or not these theories are true, one thing is for sure: baseballs are an essential part of America’s national pastime.

The economics of baseballs

While the composition of baseballs has changed over time, the overall construction has remained relatively constant. At its core, a baseball is made up of a small rubber or cork center, wrapped in yarn and then covered with leather. The specific materials used in each of these layers can vary depending on the manufacturer, but the basic structure is always the same.

One thing that has changed significantly over time is the cost of baseballs. In the early days of professional baseball balls were quite expensive, costing as much as $1 each. Today, a single ball typically costs less than $5, and a pack of 12 can be had for less than $20.

The reason for this dramatic decrease in price is largely due to changes in the construction of baseballs. In particular, the use of synthetic materials has greatly reduced the cost of manufacturing balls. For example, synthetic rubber centers are now commonly used in place of more expensive cork cores. Additionally, synthetic yarns are often used in place of natural fibers like wool.

Despite these cost-saving changes, baseballs are still subject to market forces like any other product. In general, the price of baseballs tends to be highest during periods of strong demand (such as the playoffs) and lowest during periods of weak demand (such as the off-season).

The future of baseballs

In recent years there has been a lot of debate surrounding the construction of baseballs. Some believe that the balls are too hard and are causing an increase in injuries, while others believe that the balls are fine the way they are. However, it seems that the majority of people agree that baseballs should be made of a softer material.

One material that has been proposed is cork. Cork is already used in many different industries, and it has a long history of being used in baseballs. In the past, cork was used as a core for baseballs, but it was eventually replaced with rubber because it was thought to be too soft. However, cork has many benefits that rubber does not have. For one, cork is much lighter than rubber, so it would not put as much stress on a player’s arm. Additionally, cork is easier to compress than rubber, so it would be easier for pitchers to get a good grip on the ball.

Another material that has been proposed is wool. Wool has many of the same benefits as cork, but it also has some additional benefits. For one, wool is much more absorbent than cork, so it would help to keep the ball dryer and reduce friction. Additionally, wool is a natural material that is biodegradable, so it would be better for the environment than rubber or synthetic materials.

It will likely be some time before we see any major changes to the construction of baseballs, but it is clear that there is support for change. It will be interesting to see what material eventually becomes the standard for baseballs.